Rinos is the original manufacturer of authentic, sustainable coir mats. And when it comes to sustainability, this family business has had an eye for people and the environment, for generations. So it’s only natural for Rinos to want to pass on the business to future generations in a responsible manner. The Rinos Sustainability Path is our long-term programme to achieve this, based on the United Nations Sustainable Development Goals.

Until 2030, Rinos will focus on four of the UN Sustainable Development Goals:

- decent work and growth (8)

- sustainable innovation (9)

- responsible consumption and production (12)

- undertaking climate action (13)

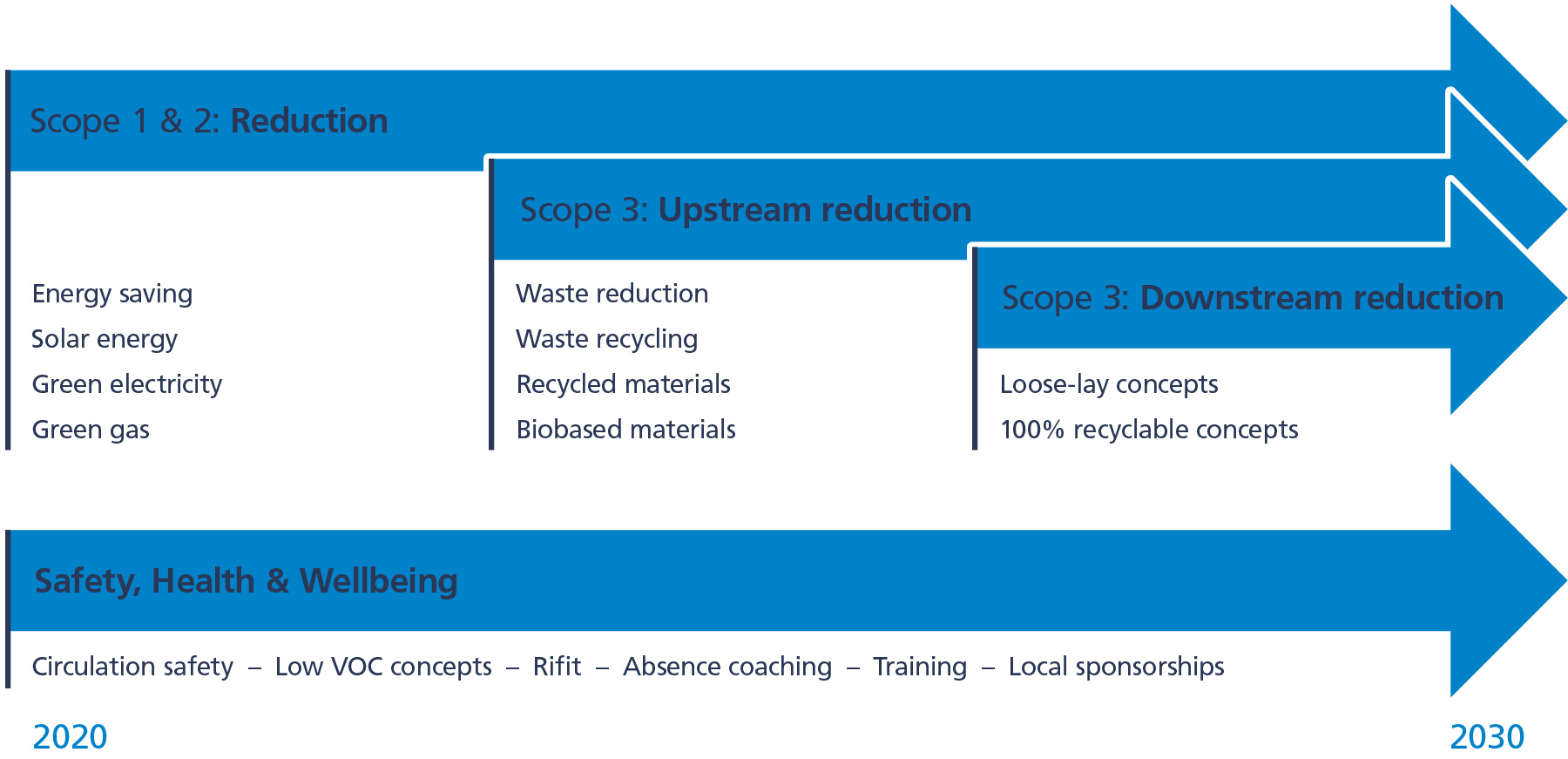

Rinos Sustainability Path

Rinos aims to contribute to sustainability in three phases. Firstly, by reducing our direct and indirect CO2 emissions (Scope 1 & 2) even further, and by moving to green energy. In 2018, we replaced our gas-fired ovens with electric heat sources, powered by solar panels. Already in 2018, we replaced our gas-fired ovens for a production with electric heating powered by solar panels.

Secondly, we are reducing the CO2 released in the extraction and processing of raw materials (Scope 3 upstream). This is achieved by reducing the amount of waste, by recycling waste more and better, by using recycled raw materials such as ECONYL® and using more renewable raw materials.

Thirdly, we aim to reduce end-of-life carbon footprint by developing new, highly recyclable products that do not require incineration.

In parallel to these three phases, we continuously promote employee health, safety and fitness. We actively contribute to the communities in which we operate: locally, nationally and internationally.

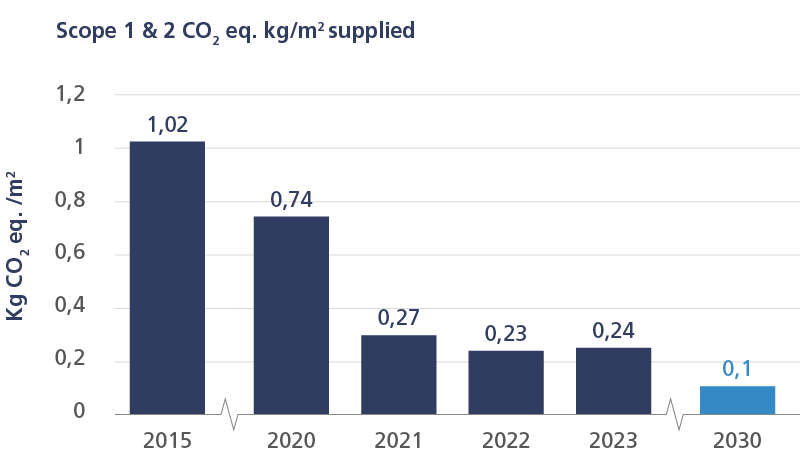

77% carbon footprint reduction

We’ve been working hard to reduce our organisation’s CO2 emissions, for a number of years. In 2023, we achieved scope 1 & 2 emissions of 0.24 Kg CO2 eq. per square metre of floor covering produced in our factory. This is a reduction of no less than 77% compared to our 2015 base year.

This was achieved by investing in more efficient electrical production processes, installing solar panels and purchasing 100% certified, green electricity. Our ambition is to reduce this even further. The last step in becoming 100% CO2 neutral will be the most difficult. It will take relatively more time and require more investment. Rinos does not use CO2 offsetting.

49% recycled, renewable raw materials

The second phase of our path is the reduction of raw materials that deplete natural resources. We assess this using the Circularity Index. This index shows the proportion of recycled and renewable raw materials used, in comparison with total raw material procurement per year. In 2023, Rinos’ Circularity Index was no less than 49%.

The use of renewable materials is embedded in Rinos’ DNA. We were originally a manufacturer of coir mats, made from the outer bark of coconuts. And we were the first to produce a walk-off mat using ECONYL® (regenerated polyamide). In 2020, we developed a PVC-free alternative to our mats, Pura Backing™.

Since January 2024, we have been using recycled calcium carbonate (chalk) as a filler in the backing of our mats. Partly because of this, our coir mats are now made from 80% biobased and recycled material.

Waste recycling

Of course, we also work on reducing our waste stream. In 2023, we managed to recycle 80% of our waste. Almost three times as much as in our base year in 2021.

Volatile Organic Compounds

Products with Pura Backing are free of chlorides and plasticisers and meet the highest requirements for the emission of Volatile Organic Compounds (VOCs). These are substances that evaporate easily at room temperature. Mats with Pura Backing™ meet criteria such as ABG/AgBB, Indoor Air Comfort Gold, BREEAM International and LEED. Our mats thus contribute to a healthy office and living environment.

Innovation: towards circular products

In the third phase, we aim to further reduce emissions by inventing and implementing new product concepts. Concepts that, for example, enable full recycling of entrance floor mats. This is a considerable challenge, not least because entrance flooring is a small part of the total flooring industry.

Rinos is transparent about the impact of our efforts on our products. We publish Environmental Product Declarations (EPD) for all of our entrance mats. This life cycle analysis is also used as the basis for improvements. The EPDs make it clear that we can only achieve improvements by working together with other parties in the chain – such as suppliers, customers and waste processors. A significant part of current CO2 emissions is caused by end-of-life incineration. Properly organised collection and take-back of entrance flooring is a particular concern for our industry.